Did you know that most bacteria in pipes and tanks live in biofilms and not free in the water? And, while free floating bacteria is easy to remove, biofilms are not.

Unfortunately pipes and tanks make an ideal environment for pathogenic and spoilage bacteria to thrive in biofilm. This is where you may find some of your nemeses: Pseudomonas, Lysteria, Staphilococcus and Salmonella.

Quality Control and Technical Managers of dairies and beverage factories often struggle with random microbial spikes. These spikes should not be ignored. They are a clear symptom of the presence of this hard-to-eliminate problem, biofilm.

Nature is always one step ahead of us in the game of survival and biofilms are proof of this. The way it transforms into an unyielding fortress while coordinating defenses and attacks, is fascinating. (Read more about this in our secret life and language of biofilms).

Bottom line, when you encounter a biofilm in your system know that it will be extremely difficult to combat.

Scientists agree that standard disinfection protocols won’t break down biofilms, especially mature biofilms. Often our clients will lament that, despite best practices, they cannot get rid of the problem. The reality is many CIP plants are not optimally designed. And as a result, there are areas that are susceptible to biofilm formation.

So, besides the costly option of redesigning your CIP plant, pipes and tanks, what can you do? Let’s look at what the international scientific community has discovered – the power of enzymes!

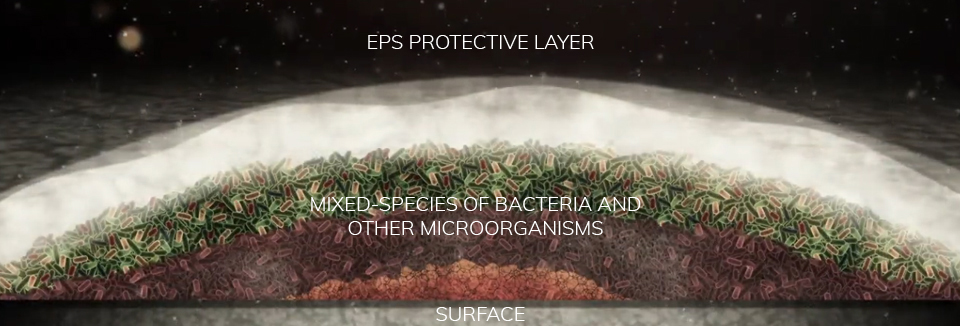

From your days in the classroom you may remember learning that biofilm protects itself by secreting an extra polymeric substance (EPS) that acts like a shield. This EPS shield is mostly proteins, carbohydrates and fats. To break through this shield, you need to match the substrate, and that is what our cocktail of enzymes does. Ripping open the shield and exposing the microorganisms. Now, when you apply disinfectant, it reaches the unprotected bacteria and destroys them.

Is our enzyme detergent different from other enzymes?

Yes. Most enzyme manufacturers use bacteria in their products. We use a unique formula of only pure, stabilised enzymes. This prevents the detection of higher counts of bacteria during Total Count tests. Best of all, our products are highly concentrated and proven effective, so a little goes a long way.

When implementing enzyme biofilm treatments, there is no need to replace your entire chemical regime. Simply treat biofilms as you find them. Or, in true HACCP style, prevent them by performing weekly biofilm treatment protocols.

Talk to us about helping you put a enzyme treatment protocol into action for your plant. info@innogiene.co.za or call 021 813 6190