The mere mention of biofilms is enough to make any microbiologist in a food factory panic. This panic is not unfounded. The threat of biofilms growing in closed processing environments is real, and the resulting microbial outbreaks can cause untold damage in the food, beverage and medical industries.

Why are biofilms in pipelines and machinery so feared?

Biofilms are usually invisible. Protected by their slimy shield, they silently multiply and spread bacteria through the system. Biofilms behave like a cancer in a human body. They are persistent. They can remain dormant for a long time. Biofilms are hard to remove. And, once you have them, they are difficult to kill. Biofilms are highly resistant to regular disinfection products. You will need some special enzymes to do the job.

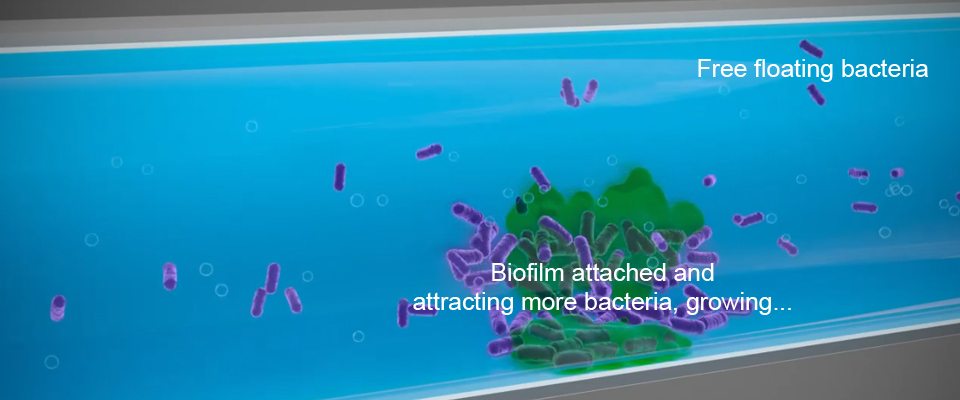

Let’s look briefly at how a biofilm forms in your pipes.

Under certain environmental conditions, free-floating bacteria in the water can attach itself to the inner wall of the pipe. Anchored here it attracts other microorganisms to join it. Building, growing and spreading to other parts of the pipe and into the machinery.

As biofilms thicken, not only do they pose a hygiene risk, but they also reduces operational efficiency. Biofilm is often the cause of poor performing heat exchangers, as well as microbially induced corrosion. If left untreated biofilms decrease productivity and can even result in a shutdown.

Once bacteria anchors and starts forming a biofilm, the resistance to cleaning significantly increases. Regular chemical disinfectants will be ineffective. So, the earlier you catch the formation of biofilms the easier it is to remove.

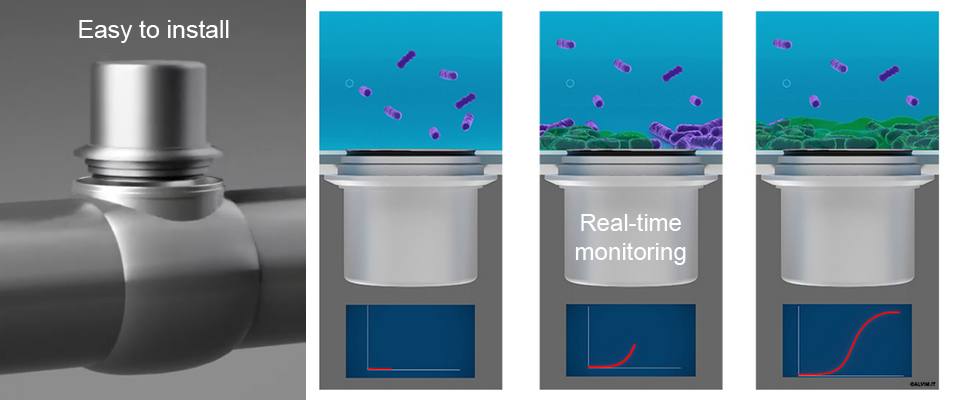

Here’s the good news. The ALVIM Biofilm Sensor can detect biofilms the moment they start to form.

The sensor emits a signal at the very moment bacteria starts to attach to the pipeline. This signal provides real-time, continuous, early-warning data online. With this important information QA’s can make data-driven decisions around the application of enzyme treatments that break down and prevent biofilms. It also helps them accurately schedule the use of chemical disinfectants. This not only saves time, money and water, but reduces the overuse of unnecessary harsh chemicals that impact our environment.

How does ALVIM’s technology work?

The ALVIM Biofilm Monitoring System reacts to the bio-electrochemical signal produced by bacteria. This signal only comes from the activity of bacteria found in biofilms. The sensor does not react to other kinds of fouling such as mineral deposits and fats.

Advantages of the ALVIM technology:

- Early detection of biofilms means easier cleaning. The high sensitivity of the sensor detects a biofilm at the very moment attachment happens.

- Continuous monitoring reduces the need for precautionary biocides when no biofilms are present.

- The sensor can detect if pipelines have been left empty.

- Biofilms reduces heat exchange efficiency by building up layers in-between the plates. Catching them early prevents this, making ROI very short.

- Biofilms can cause corrosion in the pipes if left untreated. With the ALVIM sensor’s early warning this should never happen.

- The sensor is easy to install and to use.

Get in touch with us at Innogiene to find out how the ALVIM Sensor can improve your specific hygiene requirements: info@innogiene.co.za or call us on 021 813 6190.